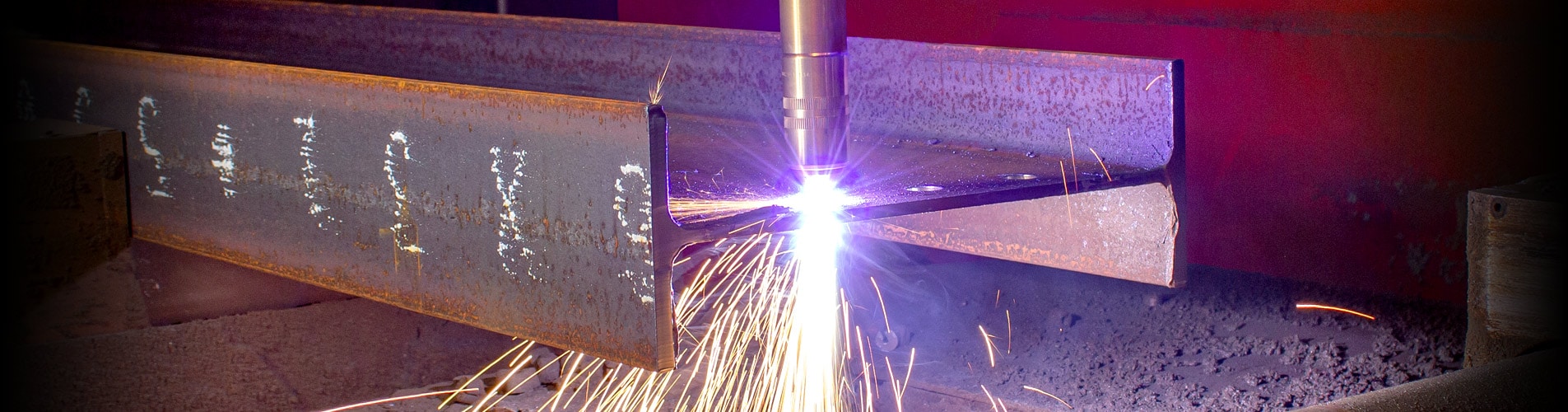

PythonX® Robotic Structural Steel and Pipe Fabrication Systems

PythonX® from Lincoln Electric® is the trusted international name in robotic fabrication systems. New machines and capabilities allow you to fabricate structural steel and pipe.

Each PythonX system is designed, built, and supported by our North American team, delivering you a premium system that ensures your machine will serve you for many years to come. Our machines are manufactured to the highest quality standards, giving you a powerful tool to expand your operation.

PythonX machines are versatile and complete solutions that automate your processing operations in your fabrication shop while providing you with increased productivity, unmatched cut quality, and predictable and consistent throughput. In addition, our signature simplicity of operation gives you the confidence to implement a new machine and start seeing a return on your investment immediately. PythonX machines deliver the solutions that you need to help your business where it counts the most . . . your bottom line.

Lincoln Electric Virtual Factory Tour

Discover the latest in combined Automation Technology offered by Lincoln Electric in this tour of a virtual factory. Our combination of machines allows for the next level of automation in your facility.